Thông tin sản phẩm

Thanks to purchase our products!

Before operating the machine,please do read the instruction carefully and take action.Thus,guarantee the machine can work in long-term,stable and reliable status.

With gradual improvement and enhancement of technology ofproducts,The comment stated in the instructions isn’t probably be in compliance with the product purchased by you i fact.Please note that final product relies on receiving current goods for prevail.

Considerations

1.Before operating the machine,please read the manual book completely,remain it good and conveniently use it for reference later.

2.Please do not amend the machine without any authorized permission of agency,or it will cause failing to operate the machine.

3.Manufacturer has no responsibility as the machine can’t work due to no any authorized permission of agency amending the machine.This amending behavior must be born by customers.

4.The machine should be set on firm ground and please keep no occupied space within 1.5 meters around the machine.

5.After finished working,please cut off the power and clean the machine.

6.Do not let the power plug overload,or cause burning fire or motor damage.

7.Do not put other objects and hands into the feeding hopper when the machine working,if doing so,it will cause pulling hands inside it or damaging the machine.

- When the machine keeps working,please do not take the upper cover out,or probably cause personal injury and destroy parts of the machine.

9.Please maintain it and add oil,replace new oil from February to June.( Please see maintenance page )

10.Please do use professional power line.If the power line is damaged,please purchase and replace it in local dealer.

11.The machine is used in ambient temperature between freezing -5℃ and 40℃,humidity 90%,power grid 220V/50Hz.

13.If the materials are blocked,it causes motor stopping working,

please shut it off immediately,and clean out the blocked materials and start working.

- Please keep it in dry,clean,ventilation place when the machine no longer works.

Technical parameters

1.Model:HK-93Z

2.Function:It can produce water pill,water honey pill and pill foodstuff.

3.Diameter of making pills:Φ6mm( Φ3、Φ4、Φ5、Φ6、Φ7 、Φ8、Φ9、Φ10、Φ12mm for options )

4.Production efficiency: 10-80kg

5.Total power supply of motor: 2200w/220V

6.Overall dimension: 750*600*900mm

7.Machine weight: 152KG

Features of technology

1.The machine adopts the design of no pull-in straight-through pill.This is domestic unique design,container structure,horizontal discharging sliver.It is simple structure,easy operation and convenient repair.

2.Discharging sliver adopts gear reducer device,stable and reliable transmission.

3.The chamber of kneading pill and cutting pill in making pills part is in the same gear-box.Lubricant oil status of mechanical components keeps good.

4.Speed of cutting pill can be adjusted by infinitive speed changer.The speed changer makes roll knives obtain 6-30 r/min and matches speed of cutting pill with speed of discharging sliver.

5.Inlet of feeding materials is big,and adopts dual-auger design,

conveniently fill materials and prevent phenomenon of overflowing materials.

6.Discharging outlet is made of nylon,safe and reliable,smooth sliver.

7.The outer side of kneading pill knives fixes wool brush which can prevent the phenomenon of making knives sticky.

Common problems & solutions

- Coarse surface: pills produced by the machine presents coarse surface,reasons as follows:

- Medical materials contain more fibre.

- Medical materials contain ores or more seashells.

- Medical powder is rough.

- Amount of adding honey is few and mixing percentage is not uniform.

- Usage of lubricant agent is insufficient.

Generally speaking,to pulverize medical materials becomes finer,to enlarge the honey usage and coat older plenty refine honey on the lubricant agent etc to solve the problems mentioned above.Also,to extract and shrink medical materials with more fibre and ores etc into sticky ointment,and then put the sticky ointment into refine honey.

- Honey pills become hard: Honey pills become extremely rigid in the process of storage.Reasons as follows:

1.The usage amount of honey is getting fewer.

2.The temperature of honey is getting lower.

3.The temperature of refining honey is so long.

4.Percentage amount of individual medicines with gelatin is getting more.

The phenomenon of forming coupling is because honey temperature rises to cause decomposition until cold-solid.

It is based on the reasons mentioned above,please ensure plenty of honey and keep honey temperature proper,the process of refining honey remains appropriate.Done all above is to solve the problems.

- Wrinkle honey pills stores for a period of time.The surface of wrinkle honey pills will present wrinkle as works or peel skin.Reasons as follows:

- Refine honey remains fresh and contains much more hydro elements.

After water evaporates,honey pills atrophy.

- Package is not tight,honey pills absorb humidity in summer season.

Water evaporation is to cause honey pills recurring bubble shrinkable phenomenon.

3.Use of lubricant oil is incorrect.

Solutions: Please control water amount of honey refine in certain level.Strong package makes it tight and please had better use candle shell to pack it,use lubricant agent properly and even.

- Anti-sand: Honey pills stores for a period of time later.It appears sugar ingredient crystallization extractor which is called as anti-sand phenomenon.Reasons as follows:

1.The quality of honey pills is poor,oil and fruit sugar are fewer.

2.Coupling is not uniform.

3.The time control of bee honey refine needs to take more exercises.

Solutions for these phenomenons:First,improve the quality of bee honey and choose great oily good bee honey.Second,strengthen bee honey refine and control temperature and time of refining honey.

- Hollow:When unfolding the honey pill,there is a small gap in the centre of the honey pill.Usual phenomenon is sugar objects extractor.Reasons are importantly based on lack of kneading skill when making honey pills.The way of overcoming this situation is to strengthen coupling and kneading pills.

- If honey pills appear moldy or make worms and oyster etc in the process of storage,the reasons are below:

1.Medical materials process and immerse in the dirty liquid.So,some microorganism or worm eggs leave in the honey pills.

2.Medical materials are polluted in the process of grinding,making pills and packing etc.

3.Package is not tight and it is polluted in the process of storage.

Solutions: Strictly obey the requirement of hygienic standard and prevent microorganism and worm eggs bringing in and polluting.

Operation instruction

Workmanship procedure:materials ready>>>materials stirring>>>discharging sliver>>>making pills

1.Before starting the machine,please clean roll shaft and contact parts of medical materials.Need to erase the oil and sterilize process.

2.Medical materials are immersed and dried,pulverized into fine powder and the powder gets through the sieve mesh with 80-100 mesh.The company and making pill machine equipping with grinding equipment have continuous feeding pulverizer machine or pulverizer machine with the grinding volume 100-1000 grams.

3.According to the property of prescription traditional Chinese medicine powder,refine adhesive combination agent in the proper status.

4.Making pill block is also called as stirring medicine.Please put medicine powder and adhesive combination agent to mix into feeding inlet of the machine,and take the nylon outlet nozzle out in the discharging outlet.Start the motor and discharge materials repeatedly for many times.After the medicine is stirring well,make sure that the medicine is not sticky for the hands,softness and hardness keep consistent,and put the medicine block on the material disc for backup.

5.Making pills: Replace outlet nozzle matching with roll shaft,start the switch of motor of kneading pill and cutting pill,and adjust the speed of cutting pill by adjustment button and the speed of cutting pill is a bit faster than one of discharging sliver.If the speed is slow,medical pills are not uniform.If the speed is fast,medical pills are hollow,usually operate governor between 25 and 35.

6.After using the machine,please take out outlet nozzle and screw rod,clean all of parts.After cleaning all,please install and put all back to the original position.

7.Please coat few grease on the surface of roll shaft and screw rod.

8.Ensure equipment keep clean and dry.

.jpg)

Specific demonstration for HK-93Z Full-automatically making pill machine

1.Materials mixing ready

2.Put it into the feeding inlet

3.Start the motor of kneading pill and switch of governor,start the switch of discharging sliver in the end.

4.The equipment adopts the design of straight-through kneading pill.

5.Discharge medical pills

6.Finished pills

.jpg)

A roll wheel

B roll wheel

Fixed auger gear

Ways of AB roll wheels symmetry: First,please fix A roll wheel,adjust B roll wheel to rotate until mutual symmetry.Start the motor of cutting pill,check AB roll wheels whether they are symmetric,If not,please readjust it.

.jpg)

Ways of replacing dual screw rod for HK-93Z full-automatically making pill machine

AB dual screw rod installs,two screw rods are divided into left and right rotating directions,please see image 1 indicator to install.If choosing image 2 to install,the machine fails discharging materials.Auger top points of two screw rods are symmetric.

Image 1 , two screw rods are in the right direction.

Image 2 , two screw rods are in the wrong direction.

.jpg)

Demonstrations of washing ways for HK-93Z full-automatically making pill machine

Loose and take out M8 screw bolt,start the switch of motor of discharging sliver and bring left materials by extrusion,and shut off the power,bring dual screw rods and outlet nozzle etc.Clean all parts and interior of feeding inlet,wait for parts dry and install them in the original positions.

Screw off and take out 4 M8 screw bolts.

Dismantle the discharging outlet device.

After dismantling dual screw rods like the image,please put them back to card ditch in the accurate position.

Common troubleshooting & solutions

|

Troubleshooting |

Reasons |

Solutions |

|

Pill shape is not round. |

Knives of making pills are are installed incorrectly. |

Readjust |

|

Pill shape is not round. |

The speed of cutting pills is fast. |

Readjust |

|

The speed of discharging sliver is not uniform. |

Mixing materials are not uniform. |

Stir again. |

|

Sticky knives |

Mixing medicine is sparse. |

Add medical powder to reduce amount of containing water. |

|

Phenomenon of breaking sliver |

Medical materials has no viscosity. |

Add adhesive combination agent. |

|

Medical sliver can’t come out. |

Outlet nozzle is blocked. |

Clean outlet nozzle. |

|

Roll shaft is damaged. |

There are hard blocks in the materials. |

Materials collect and replace roll shaft. |

Models of easily-damaged parts

|

Name of parts |

Model |

Amount |

|

Belt |

|

1 |

|

Spring |

|

2 |

|

Wool brush |

|

2 |

|

Outlet nozzle |

|

1 |

|

Roll shaft |

|

1 pair |

产品结构图

产品结构图(Structural picture of product)

进料口(Feeding inlet)

电源指示灯(Power indicator light)

电机控制区(Control area of motor)

制丸速度调节(Adjustment of making pills)

可锁止万向轮(Prevent wheel of all directions moving)

物料堆盘(Pile plate of materials)

毛刷(Wool brush)

风扇(Fan)

滚轴(Roll shaft)

出料口(Discharging outlet)

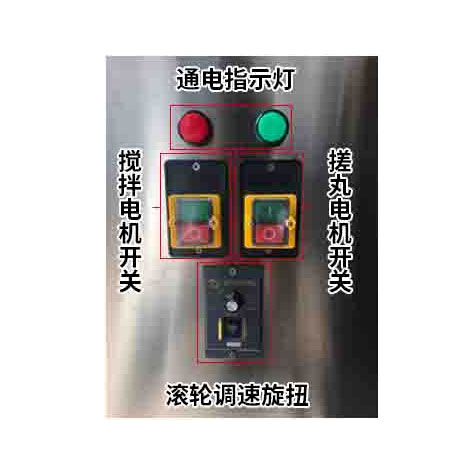

通电指示灯(Indicator light of power on)

搅拌电机开关(Switch of blender motor)

搓丸电机开关(Switch of kneading pills)

滚轮调速旋钮(Button of speed adjustment of roll wheels)

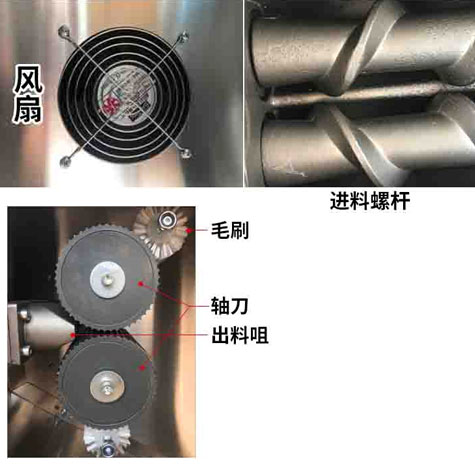

风扇(Fan)

进料螺杆(Screw rod of feeding materials)

毛刷(Wool brush)

轴刀(Shaft knives)

出料咀(Outlet nozzle)

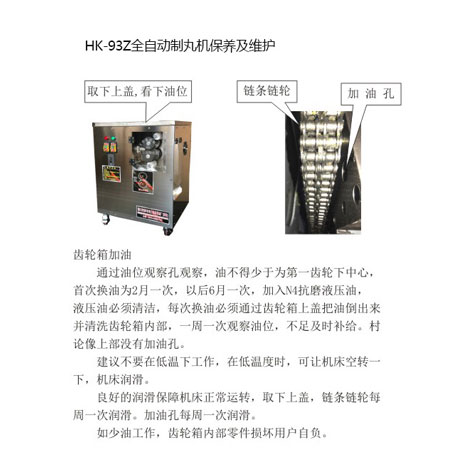

HK-93Z全自动制丸机保养及维护(Maintenance and repair for HK-93Z full-automatically making pill machine)

取下上盖,看下油位(Take off upper cover and look at the oil level)

链条链轮(Chains and chain wheels)

加油孔(Pore of adding oil)

齿轮箱加油(Adding oil for gear container)

Please observe the oil volume by observation pore of oil level.The oil can’t be less than the centre below at the first gear wheel.Please replace oil every two months at the first time,thereafter,do it every six months.Please add N4 anti-abrasion hydraulic oil which must be cleaned.When replacing oil every time,please have to pour left oil and clean interior of gear wheel container by upper cover of gear wheel container.A time a week and observe oil level,when the oil is insufficient,please replenish it in time.

Advised not to work under low temperature.When working under low temperature,

please let the lathe rotate with feeding nothing and make it lubricate.

Good lubricant guarantee the lathe to run well,take the upper cover off and ensure chains & chains wheels are lubricated a time a week.Pore of adding oil is cleaned a time a week.

If the machine works in less oil,internal parts of gear wheel container are damaged.The damage situation is born by users.